We have just successfully completed sea trials on our starboard boiler which over the past few weeks has been getting re-tubed by a specialist team from the Philippines. Because we have two Foster Wheeler type D boilers it meant we could carry on diving operations as normal during this period.

We continue to invest in our vessel, Truk Lagoon’s premier live aboard and one of the world’s best equipped dive cruisers.

Foster Wheeler type D boilers are a type of very efficient water tube boiler. Water tube boilers use small diameter tubes and a small steam drum which enable the generation of steam at high temperatures and pressures. The weight of the boiler which is much less than the equivalent fire tube boiler design enables the steam raising process to be carried out more quickly. Design arrangements for water tube boilers are flexible, high in efficiency and good natural circulation for the feed water. A later development of the water tube design was the bent tube design, this boiler has two drums an integral furnace and is often referred to as type D because of its shape. The furnace is at the side of the two drums and is surrounded on all sides by walls of tubes. These waterfall tubes are connected to upper and lower headers or a lower header and steam drum. Between the steam drum and the smaller water drum below large numbers of

smaller diameter generating tubes are fitted, these provide the main heat transfer surfaces for steam generation. Large bore pipes or downcomers are fitted between the steam and water drum to ensure good natural circulation of the water.

The Thorfinn is still operating with the same boilers that were delivered from the Foster Wheeler works in New York in November 1951 for a cost of $48,750.00.

Each boiler weights 55,700 Ib (25,265 kg) and carries an additional 7,720 Ib (3,502 kg) of water at

normal steaming level and temperature. With a boiler heating surface of 2255 sq. ft (209 sq. m) they are designed to work at up to a pressure of 250 Ib per sq. in (17.2bar).

An efficient pressurized oil burning system supplied from the UK is a capable and widely varying system burning near any type of combustible fuel cleanly, with ability for this ship to work efficiently, often on wastes and other contaminants that formerly contaminated local terrains and gardens in vicinity of island power plants. Wasting and leaking drums were creating huge pools of black oil seeping into many island aquafers when Thorfinn first arrived at Micronesia back in 1980. Now the cleaner islands have dispatched their wastes to this ship for an effective and clean disposal within our twin propulsion steam generators.

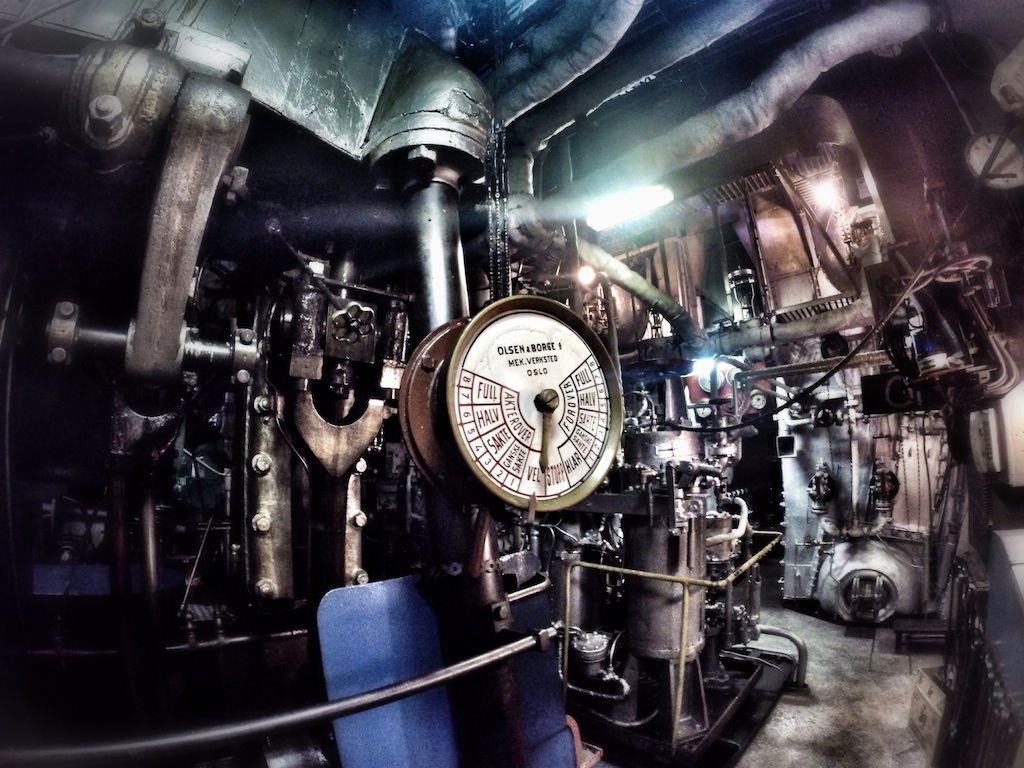

The machinery of the ship is awe inspiring to many of today’s visitors unaware of the huge mechanical systems employed below decks.